drive shaft coupling failure

Click image to enlarge. In the present article a failure analysis of a dynamometer drive shaft has been performed.

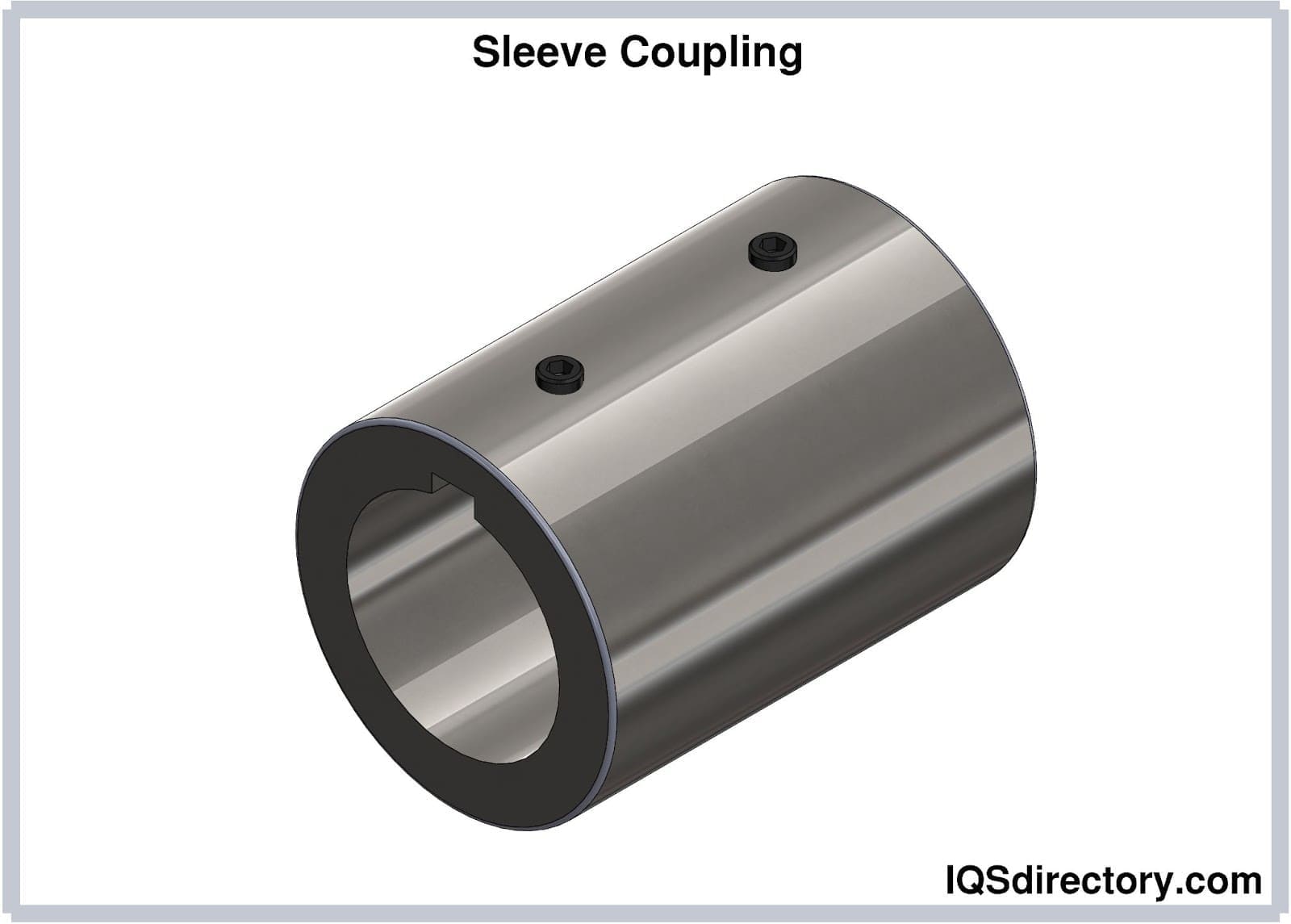

Shaft Coupling What Is It How Is It Used Types Of Roles

Drive shaft coupling failure.

. Sometimes heat can even travel through a shaft and cause coupling failure. The shaft couplings will also need to be undone for the same reason. Shaft misalignment can limit a machines performance cause excessive vibration high reaction loads and accelerated wear and often leads to premature equipment failure.

If the drive shafts universal joint revolves very fast or cannot revolve then there is an issue with your shaft. 1000 Ashwaubenon Street Green Bay WI 54304 Toll Free. Put in a new Dorman one and it has destroyed itself in just 2 months.

Worn out u-joints couplers or carrier bearings can cause the driveshaft to vibrate. If the U-joint of your drive shaft rotates too fast or fails to rotate then its a problem with your drive shaft. For this application the coupling hubs having interference fit bores torque is transmitted between the shaft and coupling hub through two methods.

If the cushioned plate option is followed this is not necessary. You need to remove the driveshaft to perform a drive shaft repair on your vehicle. The driveshaft is usually held by four bolts on each side.

The clicking noise is an audible noise that sounds like tak. Car is a 2007 V6 and had done around 460000km on the factory coupling and if I hadnt stupidly thrown the old one out I would. ARTICLE INFO A typical dynamometer drive shaft was damaged during its working condition.

The cause of driveshaft failure is the result of a combination of factors. If there is a peak torque overload that the coupling cannot handle the most likely failure mode will be a coupling hub burst or crack over a corner of the keyway. Excessive misalignment between joined shafts is one of the most common reasons for coupling failure due to the creation of loads that surpass the coupling specifications.

Here you can see teeths of coupling are damagedwear in a specific regular pattern. You may also hear sounds while the car is shuddering from the worn-out U-joint. It is important to identify high ambient temperatures that may occur at the coupling.

To analyze the failure the. If you dont get these components serviced it can lead to further damage to. Youll need to have your drive shaft replaced because you cant drive your vehicle in this condition.

Discussion Starter 1 Feb 6 2015. Which resultant into loss of power transmission to tail rotor. The cap seals of the bearings could have rust on them.

At Crane Engineering we find the root cause of coupling failure ladders up to one of the following reasons. If the shaft is to be removed the gearbox oil will need to be drained first. Disc couplings are often the best solution with their all-steel design.

If the drive shafts universal joint revolves very fast or cannot revolve then there is an issue with your shaft. Either that or the u-joint itself is not stable. In such a case the vehicle can no longer be propelled and the.

Once you remove the driveshaft you can focus on removing the universal joint. All flexible shaft couplings are designed to allow for misalignment of one. Analysis of the flexible coupling failure established that fatigue cracking in the flexplate arm at the bolted joint between the flexplate and main rotor gearbox yoke Tail rotor drive shaft coupling failure.

Had to replace my factory rear driveshaft coupling recently has a few small cracks due to age. While the most common torsional fatigue cracks start at the sharp corner stress concentration at the bottom of the keyway when couplings are poorly fitted another common appearance is the diagonal shaft crack like that shown in Fig. Although some car models can differ slightly this is the most obvious sign of a drive shaft failure.

The first step in preventing drive shaft failure is to replace the shaft. 1 the friction caused by the shaft interference fit and 2 via the surface of the key. That unfortunately has led to many motor and driven-shaft failures due to torsional-fatigue factors.

Shaft couplings are critical parts of any power transmission system providing the smooth transfer of power from one component to another. Failures are common at this location because it is generally the weak point of the coupling hub with the least amount of material to carry the load. A common symptom of a failing driveshaft is an intense shaking coming from underneath the vehicle.

Some external signs that indicate potential coupling failure include. Although some car models can differ slightly this is the most obvious sign of a drive shaft failure. The clicking noise is an audible noise that sounds like tak.

Misalignment can be caused by improper installation of the pump and motor pipe strain even bent shafts. Up to 50 of damage to rotating equipment is directly related to misalignment. The gearbox is unbolted and supported as it is moved clear and can then be lifted clear for inspection on a bench.

When the surface of the keyway is damaged the key no longer has proper contact and the shaft hub. This is because with the passage of time the bearing seal cap can rust. The first step in preventing drive shaft failure is to replace the shaft.

If your shaft is worn the lubrication system is clogged the fuel pump is clogged and there is a buildup of debris in the engine then you have a high chance of a shaft failure. Up to 8 cash back Experiencing a significant shudder when accelerating from low speed or a stopped position it can be another sign of failing driveshaft components. This failure was repeated in four cases.

That is a tell-tale sign for you to know that you have a bad drive shaft. As with any other part of the system maintenance maximizes coupling life and ensures reliable system operations. A loose U-joint or bad center bearing within the driveshaft may cause the faltering acceleration.

As per my experience after looking at coupling i think the teeths conditions of coupling indicates fretting wear and tear and then it slipped on the day of incident. Jaw-coupling inserts are also available in alternate materials that can withstand temperatures up to 480-deg F. Step one requires unbolting the bolts that are holding the drive shaft.

Drive shaft is broken from many points. Flexible Shaft Couplings can help prevent these issues by transmitting torque while compensating for parallel angular and axial misalignment between drive components.

Flexible Shaft Couplings For High Temperature Applications

Shaft Coupling What Is It How Is It Used Types Of Roles

Are Your Shaft Couplings The Best Fit For Your Application Ibt Industrial Solutions Ibt Industrial Solutions

Vetus Shaft Coupler Jeanneau Owners Network

What Is A Coupling How Does A Shaft Coupling Work Types Of Shaft Coupling

Control Flex Shaft Couplings Flexible Shaft Couplings

Mclc 35 35 F 35mm X 35mm Rigid Coupling Steel Ruland

Control Flex Shaft Couplings Flexible Shaft Couplings

Flexible Shaft Couplings For High Temperature Applications

12 Reasons For Coupling Failure And How To Avoid Them Insight Acorn Industrial Services Ltd

Block Shaft Coupling Advantages And Disadvantages

180 Land Rovers Being Recalled For Possible Driveshaft Coupling Failure Truck Trend News Range Rover Classic Land Rover Range Rover

Flexible Shaft Coupling Bc Series Oep Couplings Sleeve And Shear Pin

Shaft Coupling Definition Types Uses Working Principle Advantages Complete Guide Engineering Learn

Bellows Shaft Coupling Connects The Generator Left And The Motor Right Download Scientific Diagram

What Is Coupling Definition Types And Uses Engineering Choice